Alloy powder is a product made from elements such as iron, silicon, aluminum, chromium, nickel and molybdenum, alloyed at high temperature, then processed into powdered products through atomization or fragmentation.

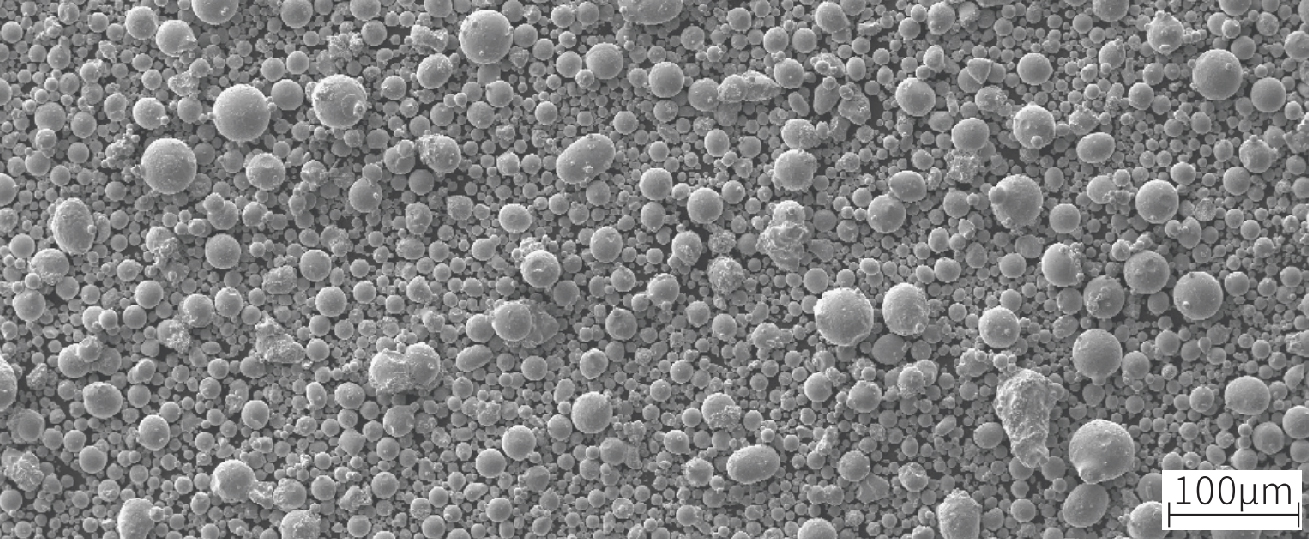

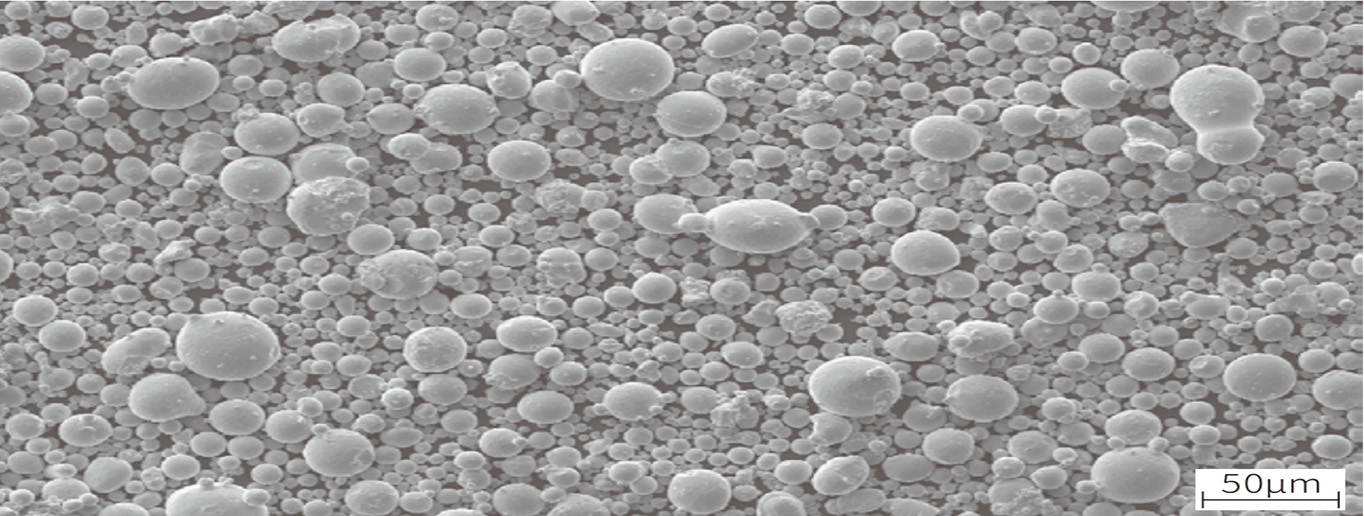

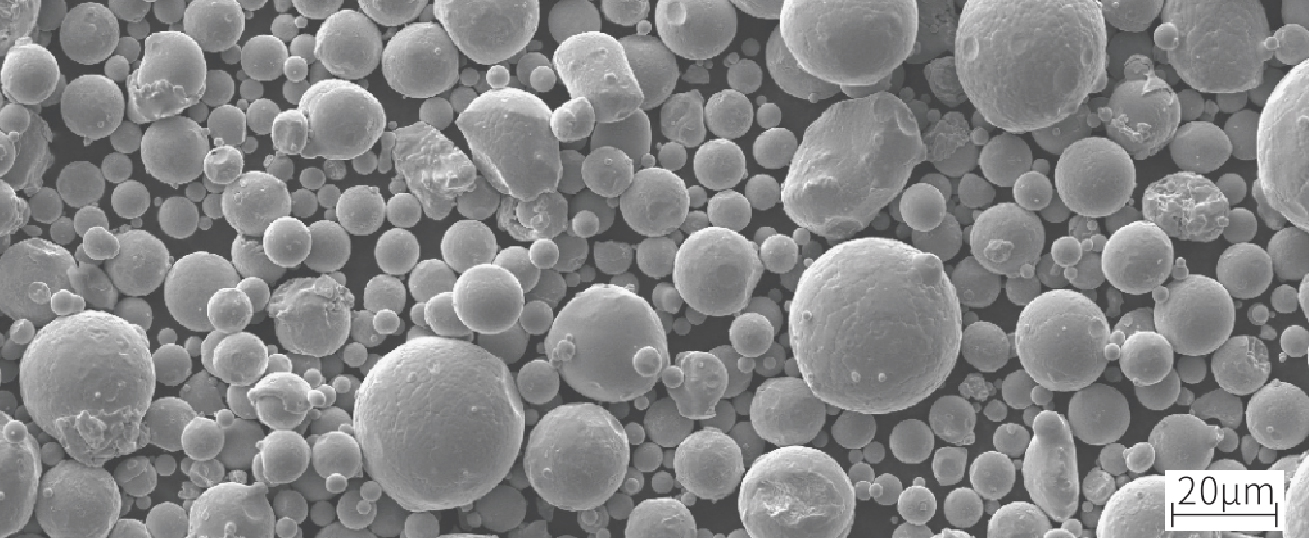

· Spherical powder with higher reliability

· High Bs, suitable for largerg current application

· Powder can achieve high density with low forming pressure

· High resistivity, low loss

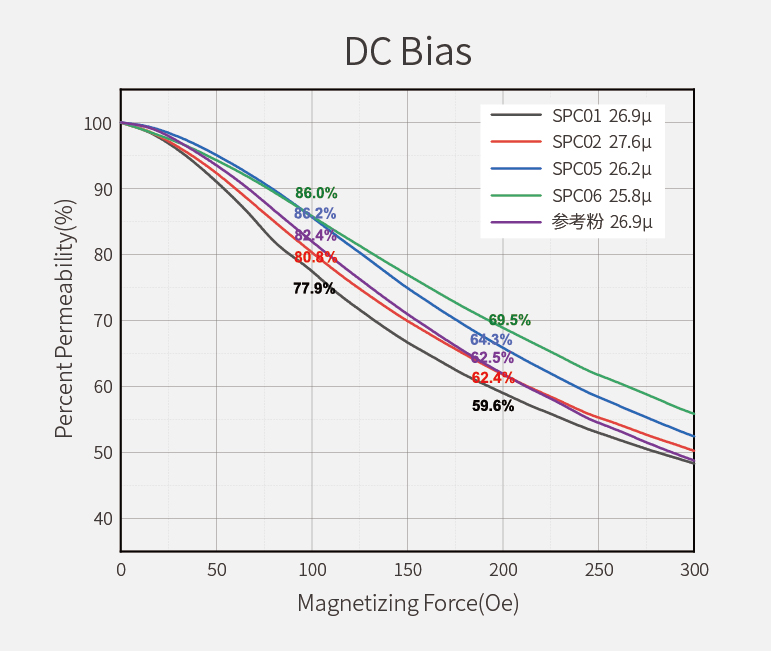

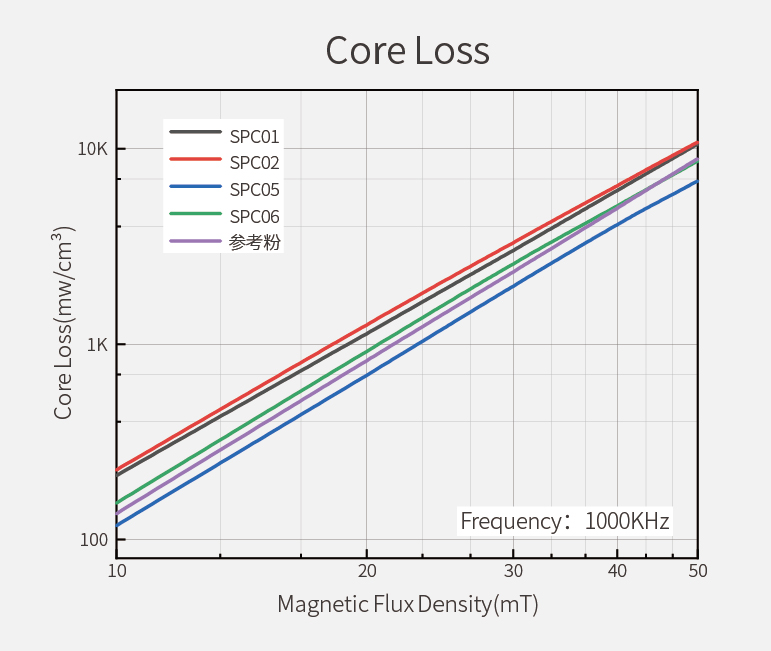

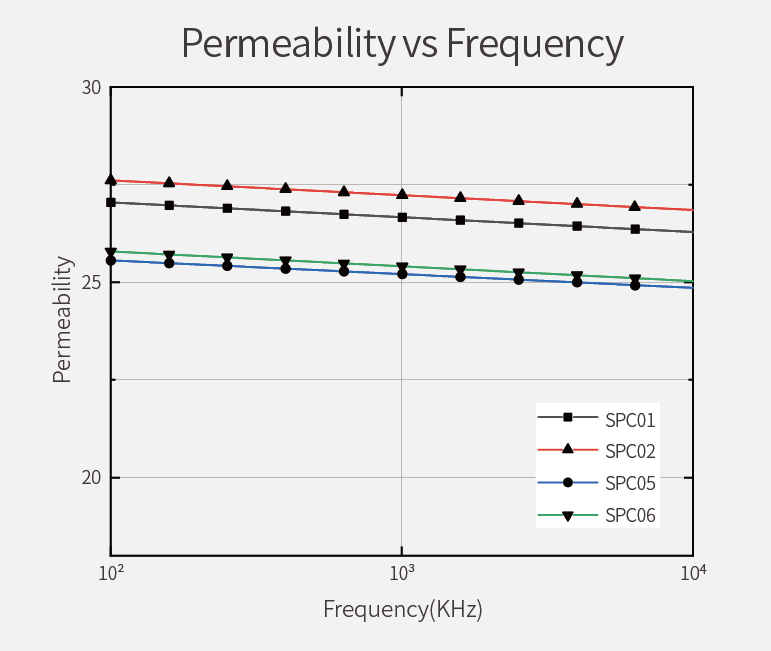

* Powder data is granulated with 3% glue, and pressed into a toridal core with 600Mpa pressures to evaluate the Electromagnetic characteristics

| Powder PN | Specification (Mesh) | D50 (μm) | A.P.density (g/cm³) | Ms (emu/g) | Oxy.Con (ppm) |

|---|---|---|---|---|---|

| SPC01 | 325 | 17~20 | ≥3.0 | 173 | ≤500 |

| SPC02 | 325 | 17~20 | ≥3.0 | 182 | ≤500 |

| SPC05 | 500 | 9~11 | ≥2.7 | 168 | ≤1200 |

| SPC06 | 500 | 9~11 | ≥2.7 | 180 | ≤1200 |

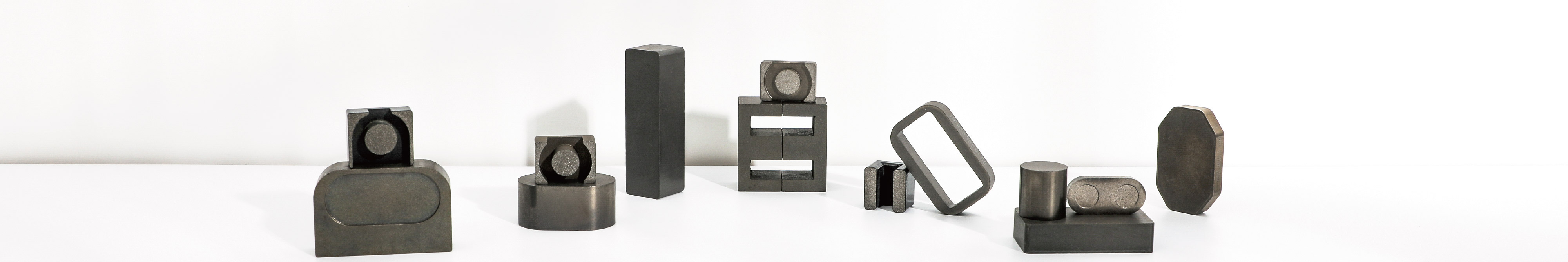

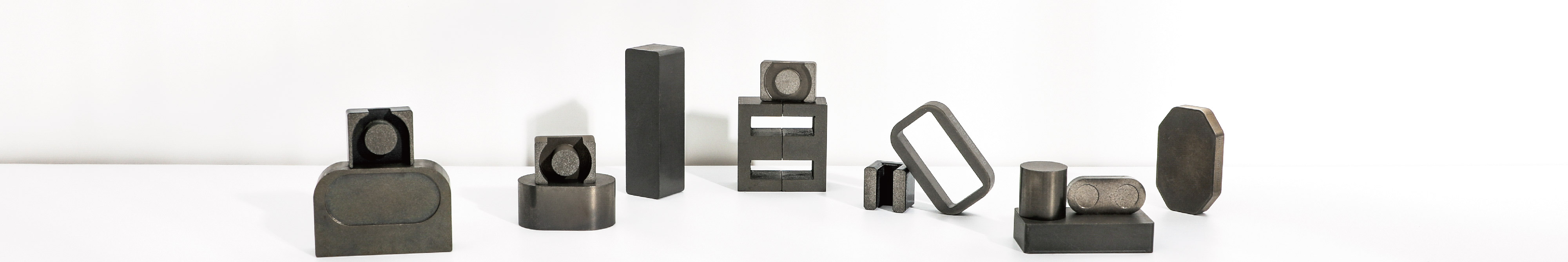

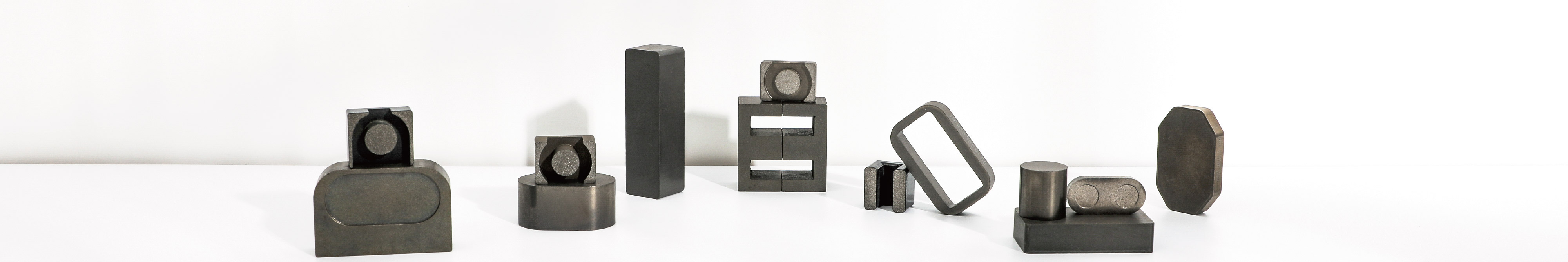

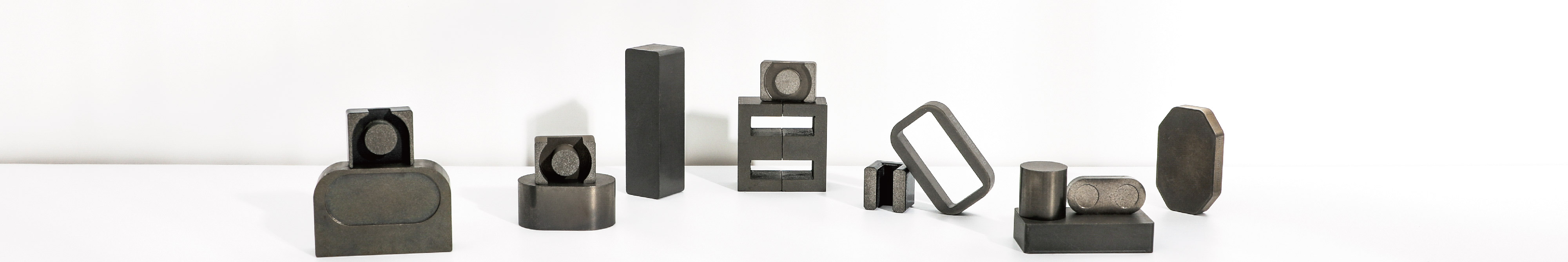

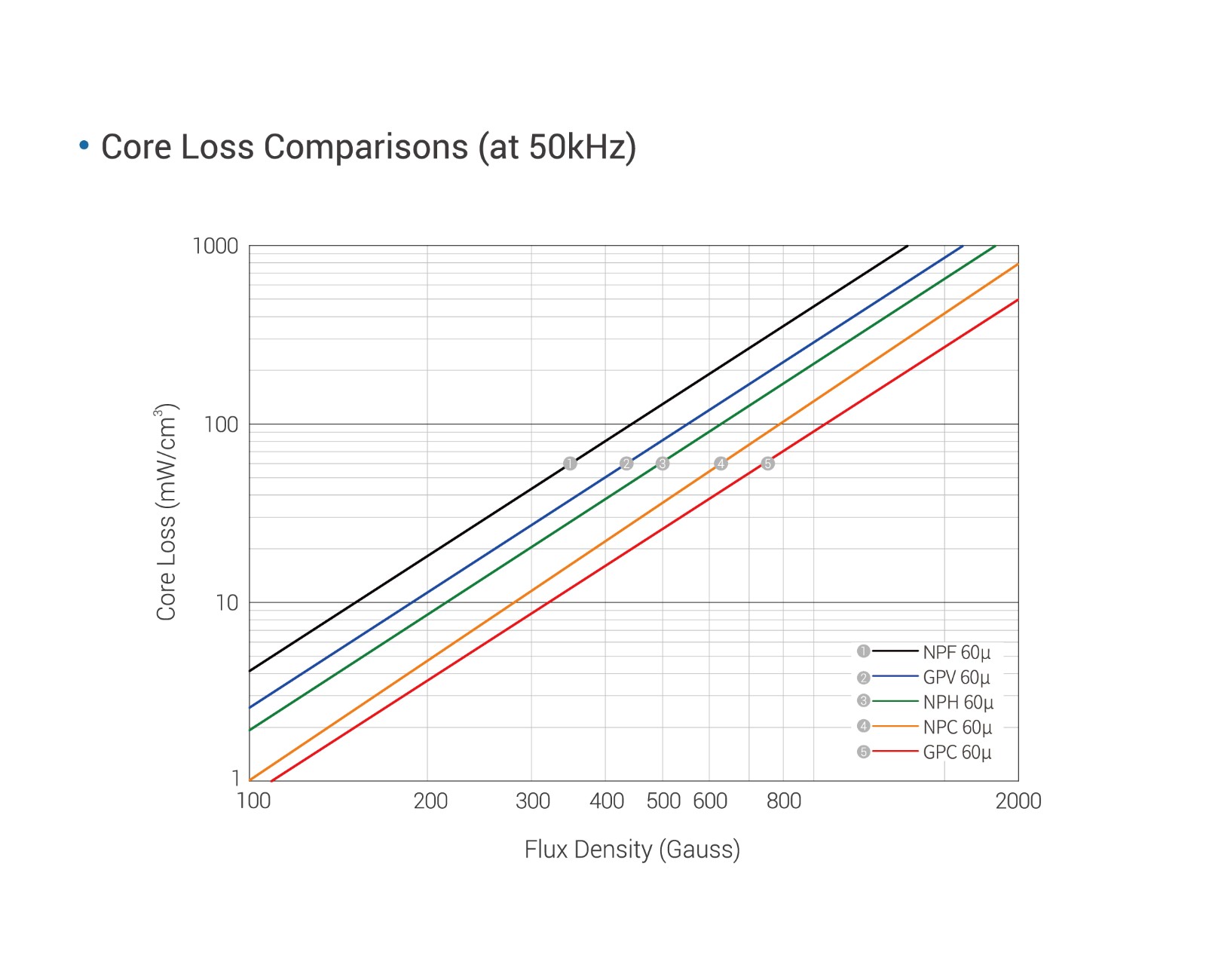

The powder core is made of a soft magnetic material with an insulating medium through metallurgical processes.

Based on the continuous iteration of materials and process technologies, we first proposed the concept of Cu-Fe sintering (CFS), and introduced a new generation of inductors. In 2023, POCO established its own brand-New Inductor.

Scan the code to follow